谘詢電話

13924666952

400-158-1606

4月15-18日,橡塑行業(ye) 年度“盛宴”,CHINAPLAS 2025國際橡塑展即將開啟,yl34511线路中心工控將亮相深圳市國際會(hui) 展中心12號館12R25,誠邀大家一同近距離感受“智能製造”的魅力!

On April 15-18, CHINAPLAS 2025 International Rubber and Plastics Exhibition, the annual "feast" of rubber and plastics industry, is about to open, and Huacheng Industrial Control will appear in Room 12R25, Hall 12 of Shenzhen International Convention and Exhibition Center. We sincerely invite everyone to feel the charm of "intelligent manufacturing" at close range!

或許你會(hui) 想問,今年yl34511线路中心工控的展台,又有哪些技術可以助力生產(chan) 呢?讓我們(men) 先與(yu) 時代前沿的AI建立對話,看看它是怎麽(me) 回答的。

Perhaps you may wonder what technologies are there at Huacheng Industrial Control's booth this year that can boost production. Let's first initiate aconversation with the cutting-edge Al of the era and see how it answers.

在橡塑行業(ye) ,製造企業(ye) 如何才能提升生產(chan) 效率並確保產(chan) 品質量?

In the rubber and plastic industry, how can manufacturing enterprises improve production efficiency and ensure product quality?

總結來看,其實AI的回答與(yu) yl34511线路中心工控在智能製造領域的實踐高度契合:係統要智能,助力高效生產(chan) ;操作要簡單,易上手易維護;數據要管理,優(you) 化生產(chan) 流程。

To sum up, in fact, AI's answer is highly consistent with Huacheng Industrial Control's practice in the field of intelligent manufacturing: the system should be intelligent and help efficient production; Simple operation, easy to use and easy to maintain; Data should be managed to optimize the production process.

聚焦控製係統,賦能智造生產(chan)

Focus control system

Empower intelligent production

yl34511线路中心工控深耕行業(ye) 20載,緊跟客戶需求,不斷創新與(yu) 突破。產(chan) 品從(cong) 早期的簡單應用到如今的複雜工藝;從(cong) 線性機器人控製係統、多關(guan) 節機器人控製係統,到具身智能雙臂協同控製係統;從(cong) 國內(nei) 市場到國際舞台。如今,yl34511线路中心工控涉及碼垛、搬運、焊錫、點膠、噴塗、折彎等場景,廣泛應用在注塑、金屬加工、3C、包裝、鋰電、新能源等行業(ye) 。助力智造企業(ye) 高效生產(chan) ,持續推動行業(ye) 進步。

Huacheng Industrial Control has been deeply involved in the industry for 20 years, keeping up with customers' needs and constantly innovating and breaking through. The products have evolved from simple applications in the early days to complex manufacturing processes nowadays; From linear robot control system and multi-joint robot control system to intelligent dual-arm cooperative control system with body; From the domestic market to the international stage. Nowadays, Huacheng Industrial Control involves palletizing, handling, soldering, dispensing, spraying, bending and other scenes, and is widely used in injection molding, metal processing, 3C, packaging, lithium battery, new energy and other industries. Help intelligent enterprises to produce efficiently and continuously promote the progress of the industry.

明星展品亮相

近距離體(ti) 驗智造魅力

Star exhibits appear and experience the charm

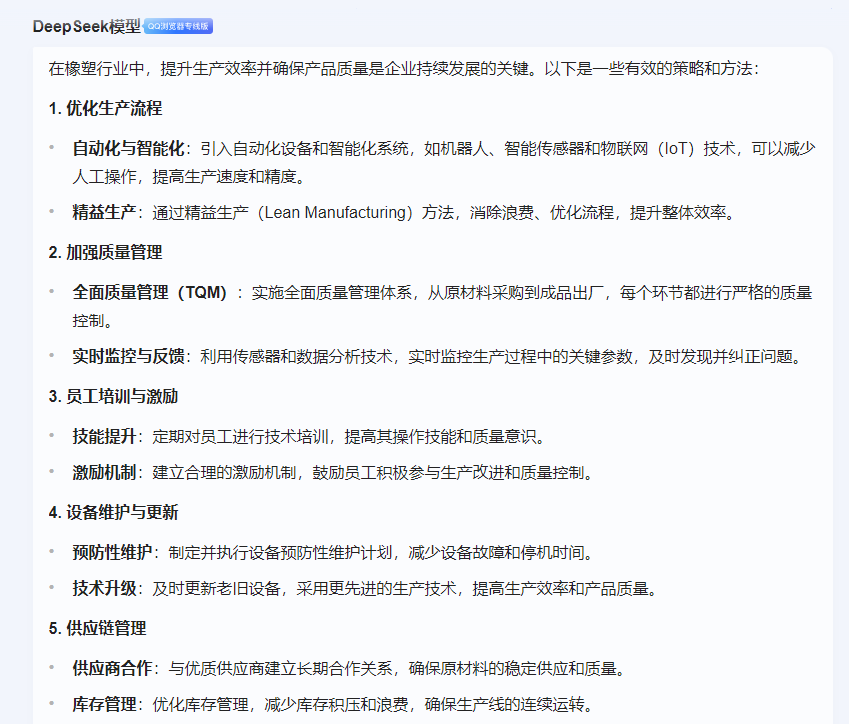

注塑線性機器人控製係統

Control system of injection molding linear robot

At the exhibition site, Huacheng Industrial Control will present a variety of injection control system products. The "Motion Control System of High Performance Multi-axis Injection Manipulator" independently developed by Huacheng Industrial Control Co., Ltd. Only takes an average of 0.395 seconds in the mechanical hand mold, and the Control accuracy reaches 0.01 mm within a movement stroke of 3 meters. The whole process is stable and efficient! Huacheng industrial control injection molding linear robot control system has penetrated into the production of all walks of life by virtue of its advantages in technical design, safety guarantee and cost control.

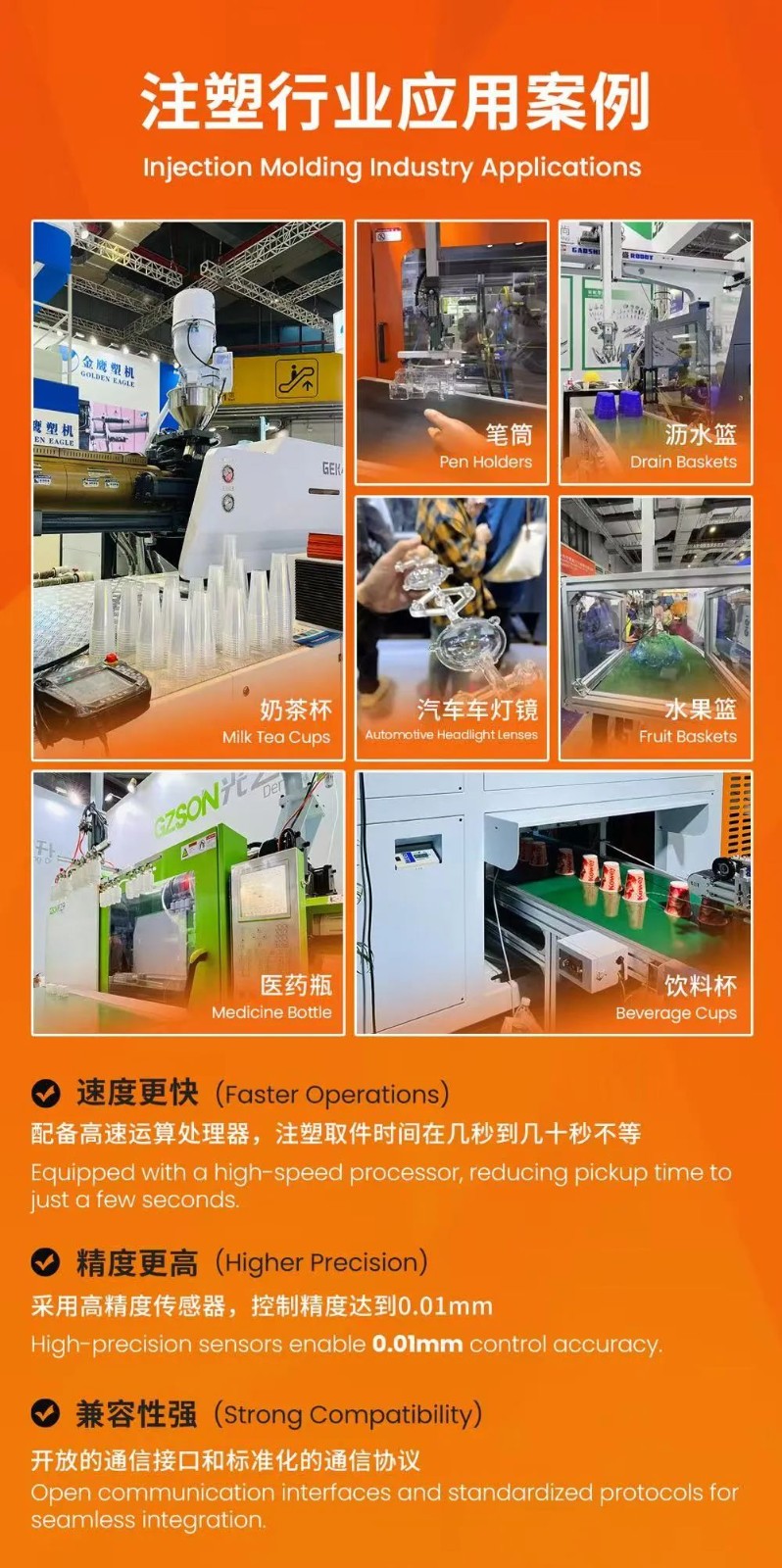

多關(guan) 節機器人控製係統

Multi-joint robot control system

多關(guan) 節機器人控製係統是針對多關(guan) 節機器人應用而推出的高效解決(jue) 方案,適用於(yu) 注塑取出、上下料、碼垛、焊接等工業(ye) 場景。其中,GC-RX 係列產(chan) 品是yl34511线路中心工控針對通用型串聯關(guan) 節機器人推出的驅控一體(ti) 控製櫃,內(nei) 置6路電機抱閘控製,可選配重載線,免除焊線,減少維護成本。支持中英文LCD顯示,具有柔性、多維度、多自由度特點。QC-R6M是新一代板卡級驅控一體(ti) 控製係統,采用全新架構伺服控製係統,體(ti) 積更小,集成度更高。在響應速度、控製精度等性能上有明顯提升,可滿足更加複雜的自動化場景。

Multi-joint robot control system is an efficient solution for multi-joint robot application, which is suitable for industrial scenes such as injection taking out, loading and unloading, palletizing and welding. Among them, GC-RX series products are drive and control integrated control cabinets launched by Huacheng Industrial Control for universal serial joint robots. Built-in 6-way motor locking control, optional heavy-duty wire, eliminating welding wire and reducing maintenance cost. Support Chinese and English LCD display, with flexibility, multi-dimension and multi-degree of freedom. QC-R6M is a new generation of board-level drive and control integrated control system, which adopts the same service control system with a brand-new architecture, with smaller volume and higher integration. The response speed and control accuracy are obviously improved, which can meet more complex automation scenes.

工業(ye) 雲(yun) 平台

Huacheng Industrial Cloud Platform, using cloud computing architecture and big data processing capabilities, The operation data of the equipment can be transmitted to the cloud within 30 minutes of deployment and easily realize fast data transmission. It can not only remotely monitor industrial equipment, but also conduct in-depth processing and analysis through the big data center on the cloud.

CHINAPLAS 2025 國際橡塑展是您看技術、占先機、拓人脈的機會(hui) 。歡迎蒞臨(lin) 12號館12R25 yl34511线路中心工控展台,與(yu) 我們(men) 一同探索智能製造的無限可能!

CHINAPLAS 2025 International Rubber & Plastic Exhibition is an opportunity for you to see the technology, take the lead and expand your contacts. Welcome to the 12R25 Huacheng Industrial Control booth in Hall 12, and explore the infinite possibilities of intelligent manufacturing with us!

版權所有 © 深圳市yl34511线路中心工業(ye) 控製股份有限公司 未經許可不得複製、轉載或摘編,違者必究 版權聲明

Copyright © Shenzhen Huacheng Industrial Control Co., Ltd. All Rights Reserved.

網站ICP備案號:

技術支持: